Key considerations for Type-C fast charging connector mold development

Type-C fast charging connectorPlaying a key role in modern electronic devices, its quality and performance are therefore crucial. To ensure high-quality manufacturing of Type-C fast charging connectors, the mold development process is crucial. This article will explore Type-C fast charging connections in detail Key considerations in tool mold development to ensure product performance and reliability.

1. Material selection:

The performance and durability of the Type-C fast charging connector directly depends on the quality of the selected material. Before mold development, it is important to carefully select the appropriate material. Generally, the main components of the connector should be made of high strength, high conductivity and resistance. Corroded metal materials, such as copper alloy or stainless steel. In addition, the casing usually uses engineering plastics to ensure that it has sufficient stiffness and wear resistance.

2. Structural design:

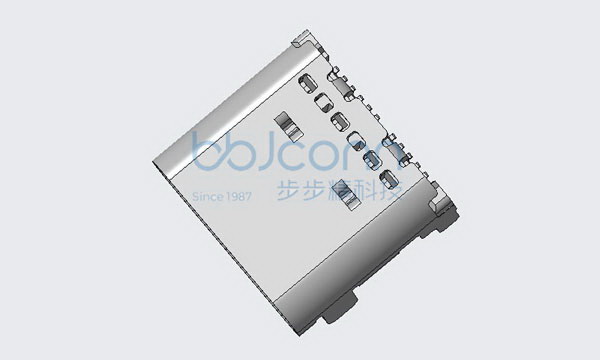

Before designing the mold, the structure of the Type-C fast charging connector must be carefully considered. The internal structure of the connector should fully consider the requirements for signal transmission, power transmission, and mechanical connection. In addition, pay attention to the shape and arrangement of the contact points during design , to ensure reliable connection and easy plugging and unplugging.

3. Mold manufacturing accuracy:

The manufacturing accuracy of the mold directly affects the molding quality of the connector. High-precision molds can ensure that the size and shape of the connector are accurate, thereby avoiding the production of substandard products. In the mold manufacturing process, high-quality materials need to be used and strictly controlled Manufacturing process to ensure the precision and durability of the mold.

4. Cooling system design:

The cooling system design of the mold is an easily overlooked but critical aspect in mold development. A good cooling system can effectively control the mold temperature and prevent overheating and deformation, thereby improving the mold life and product quality. The design of the cooling system should take the mold into consideration different parts to ensure even cooling.

5. Mold maintenance:

Once the Type-C fast charging connector mold is put into use, regular maintenance and upkeep are crucial. Regular cleaning and lubrication of the mold can extend the life of the mold and ensure the consistency of product quality. At the same time, mold maintenance records need to be established to track the mold usage history and maintenance status.

6. Testing and Verification:

After the mold development is completed, strict testing and verification must be carried out. This includes a comprehensive inspection of the size, shape and performance of the mold to ensure that it meets the design requirements. In addition, simulated production testing of the mold can be carried out to evaluate the performance of the mold in actual production performance in.

7. Continuous improvement:

Mold development is not a one-time job. Continuous improvement is the key to ensuring connector quality and production efficiency. Regularly evaluate the performance of the mold, analyze the root cause of the problem, and take corrective measures to continuously improve the quality and life of the mold.

Type-C fast charging connector mold development is a key step to ensure product performance and reliability. Through selected materials, optimized structural design, high-precision manufacturing, cooling system design, mold maintenance, testing and continuous improvement, the connector’s High-quality manufacturing, meeting market demand, improving customer satisfaction, and ensuring product competitiveness. Connector mold development requires a high degree of expertise and attention to detail, but these investments will pay off in terms of product quality and market performance.