Stamping process and quality control of TYPE-C patch

TYPE-C patchAs one of the important components of connected electronic devices, they play a key role in connecting the world. They are usually used in various consumer electronics products, such as smartphones, tablets, headphones, etc., and are popular for their compact and efficient design. This article will explore the stamping process and quality control of TYPE-C patches to ensure their reliability and performance in equipment.

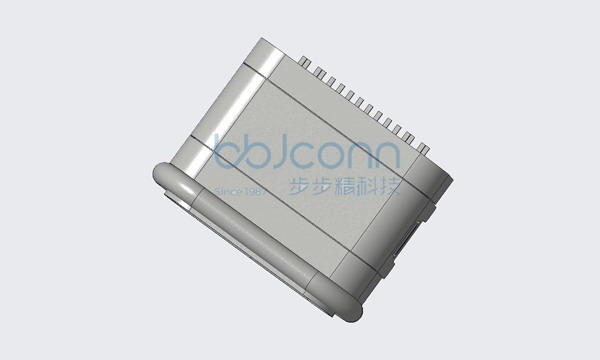

Basic structure of TYPE-C patch

TYPE-C patch is a small connector, usually with a metal shell, used to connect electronic signals and power between devices. They usually include 2 parts: a plug and a socket. The plug is used to connect to the output port of the device, and The socket is connected to the receiving port. Quality control is key to ensuring accurate matching and connection performance of these 2 parts.

The importance of stamping process

The manufacturing of TYPE-C patches usually involves a stamping process, which is a critical step that affects the performance and reliability of the patch. The stamping process involves punching sheet metal into the desired shape to create the housings for plugs and sockets. This process requires high-precision engineering control to ensure that the size and shape of each patch is accurate.

Accuracy and patch performance

The accuracy of the stamping process directly affects the performance of TYPE-C patches. If the sizes of the patches are inconsistent or incorrectly shaped, they may not be inserted into the device port correctly, causing connection problems. This may affect the functionality of the device or even cause damage to the device. .

Therefore, manufacturers need to use highly automated stamping equipment and precision molds to ensure that the shell of each TYPE-C patch meets strict specifications. Precise control of stamping force, stamping depth and shape is to ensure the consistency of each patch. The essential.

Material selection and durability

The shell of the TYPE-C patch is usually made of metal materials, such as aluminum alloy or stainless steel. The choice of material is crucial to the durability and performance of the patch. Different materials have different thermal conductivity, corrosion resistance and mechanical strength, These properties will directly affect the performance of the patch during use.

Manufacturers need to carefully select materials to ensure that they have sufficient strength to prevent bending or breaking during normal use. At the same time, the surface treatment of the materials is also important to improve the corrosion resistance of the patch and ensure its long-term reliability sex.

Quality control and reliability testing

In addition to the stamping process and material selection, quality control is also the key to ensuring the performance of TYPE-C patches. Manufacturers need to implement strict quality control processes to check the size, shape and appearance of each patch. Automatic visual inspection systems and precision Measuring equipment is often used to detect defective patches.

In addition, reliability testing is also an integral part. TYPE-C patches usually need to withstand thousands of plugging and unplugging cycles, so manufacturers will perform plugging and unplugging tests to ensure that they can maintain stable performance in long-term use. These tests can Simulate daily use conditions to ensure the reliability of TYPE-C patches.

As a key connection component of modern electronic equipment, TYPE-C patch’s stamping process and quality control are crucial. Precise manufacturing process, appropriate material selection and strict quality control process are the key to ensuring the reliability and performance of TYPE-C patch The key. Only through these measures can manufacturers provide high-quality patches, meet consumers' needs for reliable connections, and ensure the normal operation of equipment. Through continuous improvement of processes and quality control, TYPE-C patches will continue to play an important role in connection. Plays a vital role on the world's roads.