Overcoming challenges and exploring the development path of waterproof Type-C

WaterproofType-CThe development of technology has brought revolutionary changes to electronic devices, allowing us to remain connected in humid or underwater environments. However, achieving waterproof Type-C is not easy and faces multiple challenges during the development process. This article will discuss Various technical difficulties faced in developing waterproof Type-C interfaces, and solutions to overcome these problems.

Analysis of the Difficulties of Waterproof Type-C

The difficulty in developing waterproof Type-C is to ensure that it can still maintain stable connection performance in the underwater environment. This requires the interface to have excellent waterproof performance, not only to resist water penetration, but also to ensure that it can survive in the underwater environment The stability of the electrical connection. Therefore, when designing waterproof Type-C, the following key difficulties need to be considered.

Material selection and waterproof sealing

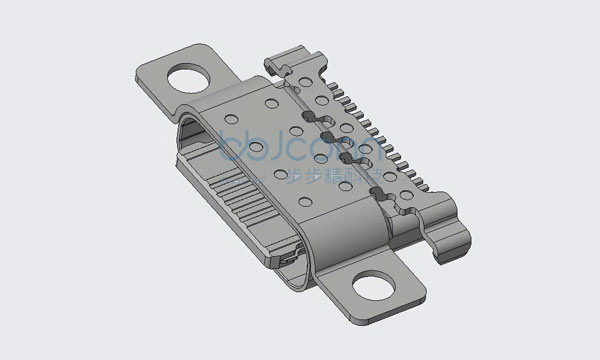

The development of waterproof Type-C first needs to consider the selection of materials. Suitable materials should have good water resistance and can effectively prevent moisture from entering the interface. For this reason, engineers often use special waterproof sealing materials to seal Type-C. The key parts of the -C interface are tightly sealed to ensure that water does not penetrate into the interior of the connector.

Interface structure design and waterproof barrier

Another challenge is to ensure that the structural design of the Type-C interface can be waterproof without affecting its normal connection performance. This requires carefully designing the interface structure and adding a waterproof barrier, which can effectively isolate moisture and maintain the stability of the connection. At the same time , it is also necessary to consider the impact of the waterproof barrier on heat dissipation to avoid overheating of the interface caused by the waterproof barrier and affecting the normal use of the device.

Waterproof testing and certification standards

In order to ensure the quality and reliability of waterproof Type-C, strict waterproof testing is required during the development process. These tests include water pressure testing, water depth testing, and underwater connection stability testing to verify that waterproof Type-C can withstand various types of water. Reliability and stability in the environment. In addition, it needs to comply with relevant waterproof certification standards, such as IP67 or IP68, etc., to ensure that the product can be recognized in the market.

Packaging process and reliability guarantee

Finally, in order to ensure the long-term reliability of waterproof Type-C, the packaging process is also a crucial part. Engineers need to choose an appropriate packaging process to ensure that the sealing performance of waterproof Type-C can withstand long-term use and various environmental tests. .At the same time, factors affecting the service life also need to be considered, such as whether frequent plugging and unplugging operations will affect the stability of the waterproof barrier.

Although there are many challenges in developing waterproof Type-C, with the continuous advancement of material science and process technology, more and more solutions have been proposed and applied. Through continuous optimization and innovation of materials, structures, testing and packaging processes , the reliability and stability of waterproof Type-C will continue to improve, providing users with a more stable and reliable guarantee for the connection experience in humid environments. In future development, we have reason to believe that waterproof Type-C will Become an indispensable and important part of electronic equipment.