Imported punch machines improve Type-C quality

Type-C connectorIt has become an important standard in modern electronic devices for achieving high-speed data transmission and fast charging. However, the quality of Type-C connector is directly related to the reliability of the connection, transmission rate and user experience. During the manufacturing process, imported Punch machines can significantly improve the quality of Type-C connectors. This article will deeply explore the impact of imported punch machines on Type-C quality.

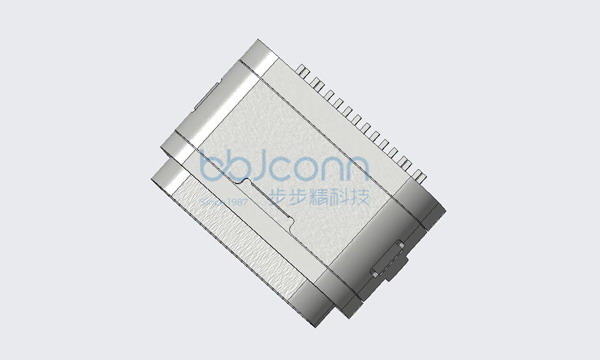

The Importance of Type-C Connectors

Type-C connector is widely used in smartphones, tablets, laptops, peripherals and many other electronic products. It has the characteristics of reversible plugging, high bandwidth, and supports multiple protocols (such as USB, Thunderbolt), making Users are able to achieve high-speed data transmission and fast charging. However, the performance of Type-C connectors depends on its manufacturing quality, including connector accuracy, impedance consistency, material quality and other factors. Imported punch machines can play a key role in these aspects.

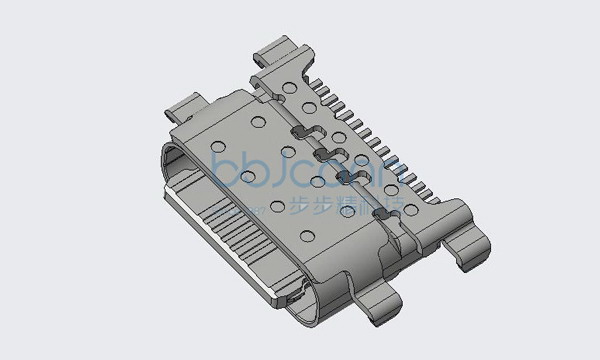

The function of imported punch press

The imported punch machine is a high-precision mechanical equipment used for punching, cutting and forming operations on metal or plastic sheets. In the production of Type-C connectors, the imported punch machine can be used in the following key steps to improve the quality of the product. quality:

1. Precise pin manufacturing: The pins of the Type-C connector must be precisely manufactured to ensure the reliability of plugging and unplugging and the stability of contact. The imported punching machine can achieve high-precision metal stamping to ensure the consistency and stability of the pins. accuracy, reducing the risk of wear and failure during plugging and unplugging.

2. Impedance consistency: In high-frequency applications, impedance consistency is crucial for signal transmission. Imported punching machines can ensure that the circuit board and signal path inside the connector have consistent impedance, thereby reducing signal reflection and distortion. This helps To maintain the quality of high-speed data transmission.

3. Material processing: Type-C connectors are usually made of metal alloy or high-quality plastic. Imported punch machines can be used for precise cutting and shaping of materials, ensuring the appearance and structural quality of the connector. This helps to improve the durability of the product Sex and appearance.

4. High production capacity: Imported punch machines usually have high production capacity and can achieve fast and precise manufacturing processes. This is crucial to meet market demand and quickly deliver Type-C connectors.

The relationship between imported punch machines and Type-C quality

The use of imported punch machines is directly related to the manufacturing of Type-C connectors, which helps to improve the quality and performance of products. The following is the impact of imported punch machines on Type-C quality:

1. Precise manufacturing: Imported punch machines have a high degree of accuracy and are able to manufacture precise connector parts, such as pins and shells. This helps ensure the reliability and durability of the connector.

2. Impedance consistency: Imported punching machines can ensure the consistency of the circuit board and signal path inside the connector, thereby reducing loss and interference in signal transmission and improving the quality of data transmission.

3. High-quality material processing: Imported punch machines can be used for high-quality material processing to ensure the appearance and structural quality of the connector. This helps to improve the appearance appeal and user experience of the product.

4. Improve production efficiency: The high production capacity of imported punch machines can ensure the mass production of Type-C connectors to meet market demand. This helps to improve production efficiency and reduce costs.

Imported punch machines play a key role in the manufacturing of Type-C connectors and have a significant impact on the quality and performance of the product. Precise pin manufacturing, impedance consistency, high-quality material processing, and high productivity all contribute to improving Type-C connectors. C connector reliability, transmission quality and user experience. Therefore, choosing a high-quality imported punch machine is crucial to manufacturing high-quality Type-C connectors, which will promote the development of modern electronic equipment and satisfy users' demand for high-speed data transmission. and the demand for fast charging. In the manufacturing process of Type-C connectors, manufacturers should make full use of the advantages of imported punch machines to ensure that the quality of products reaches the highest level. This will help meet market demand, improve competitiveness, and provide Provide users with an excellent connectivity experience.