Appearance inspection of TYPE-C patches: the key to improving quality and efficiency

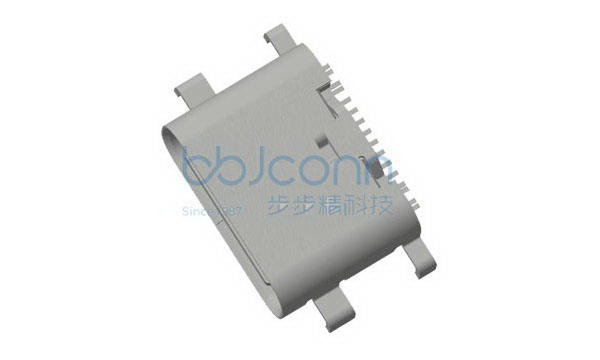

TYPE-C patchAs an important connecting device in modern electronic equipment, it is widely used because of its high-speed transmission and reversible insertion characteristics. As the market improves product quality requirements, the appearance inspection of TYPE-C patches is particularly important. This not only involves The functional reliability of the product also directly affects the user experience and the reputation of the brand. This article will deeply explore the significance, methods and future development trends of the appearance inspection of TYPE-C patches.

The appearance inspection of TYPE-C patches is first of all an important step to ensure that the product meets the design specifications and quality standards. During the production process, any minor flaws or failures will lead to a decrease in equipment performance and even cause safety hazards. For example, TYPE-C If there is a weak or missing solder joint in the C patch, it may lead to poor connection and affect the stability of data transmission. Therefore, strict appearance inspection can effectively reduce these potential risks and ensure the reliability of the final product.

There are various appearance inspection methods for TYPE-C patches, mainly including manual inspection and automated inspection. Although manual inspection can find tiny defects in some cases, it is less efficient and easily affected by human factors. In contrast, the automated inspection system can greatly improve the accuracy and efficiency of inspection through visual recognition technology. Using high-resolution cameras and image processing algorithms, the automated system can quickly identify appearance defects of TYPE-C patches, such as scratches and deformations. , color unevenness, etc., thus reducing human errors and improving detection efficiency.

The appearance inspection of TYPE-C patches can also use machine learning and artificial intelligence technology to further enhance the intelligence level of inspection. By analyzing a large amount of inspection data, machine learning algorithms can continuously optimize the inspection model and improve the identification of different types of defects. efficiency. This intelligent detection method not only improves the accuracy of detection, but also reduces labor costs and brings higher economic benefits to enterprises.

The appearance inspection of TYPE-C patches plays a vital role in quality control. With the advancement of science and technology, more and more companies are beginning to pay attention to this link. Many industry standards and quality management systems are also constantly being improved. To promote the development of appearance inspection technology for TYPE-C patches. For example, international standards such as ISO 9001 and IATF 16949 have put forward clear requirements for the quality control of electronic products and promoted the standardization and systematization of appearance inspection technology.

The future trend of appearance inspection of TYPE-C patches will be towards intelligence, automation and precision. With the continuous maturity of image recognition and artificial intelligence technology, it is expected that future inspection equipment will be more intelligent, capable of real-time monitoring of production lines, and Promptly alarm when abnormalities occur. At the same time, combined with big data analysis technology, companies can have a deeper understanding of potential problems in the production process, take preventive measures in advance, and further improve product quality.

The appearance inspection of TYPE-C patches is not only a necessary step to improve product quality, but also an important guarantee for enterprises to remain invincible in fierce market competition. By introducing advanced inspection technology and management concepts, enterprises can not only improve inspection efficiency , reduce costs, and also enhance customers' trust and enhance brand image. In the future, the appearance inspection of TYPE-C patches will continue to develop in a higher standard and smarter direction, providing a strong guarantee for the quality of electronic products. support.

In general, the appearance inspection of TYPE-C patches is a complex and important process, involving a variety of technologies and management concepts. Through continuous innovation and improvement, companies can effectively improve the quality of their products, meet market demand, and achieve Sustainable development. With the advancement of science and technology and changes in the market, the appearance inspection of TYPE-C patches will surely face more opportunities and challenges.