Analysis of the application and advantages of Type-C connectors in the field of industrial HUB

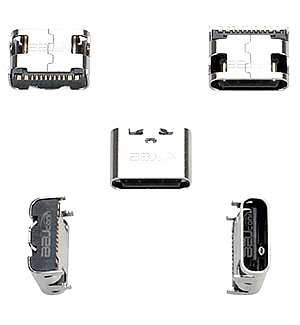

With the continuous advancement of technology, USBType-C connectorBecause of its compact, efficient and reversible pluggable design, it has quickly become a standard interface in various electronic devices. Especially in the field of industrial HUB, Type-C connectors have gradually replaced traditional connectors with their excellent transmission performance, compatibility and durability. The interface has become a key component. This article will explore the application characteristics of Type-C connectors in the field of industrial HUB and the advantages they bring.

Type-C connector improves transmission efficiency of industrial HUB equipment

One of the biggest advantages of the Type-C connector is its high-speed data transmission capability. Traditional USB interfaces often face bandwidth and speed bottlenecks, while the maximum transmission speed of the Type-C connector can reach 40Gbps (through the USB4 standard), which is far ahead of the previous generation USB interface. This makes the Type-C connector the most popular in industrial HU Applications in the B field have become an ideal choice to improve the efficiency of system data exchange. For example, in industrial automation systems, large amounts of data need to be transmitted quickly and stably between various sensors and control equipment. Type-C connectors can greatly improve their performance with their high bandwidth. The overall performance of the industrial data network meets the needs of complex applications for high-speed data flow.

Type-C connector enhances device compatibility and flexibility

Another notable feature of Type-C connectors in the industrial HUB field is its excellent compatibility. Traditional industrial equipment often uses different types of interfaces (such as RS232, DB9, etc.), and this diverse interface type often leads to equipment The connection between them is difficult and even requires an additional converter. The Type-C connector serves as a unified interface The Type-C interface standard is compatible with various types of equipment, whether computers, sensors or control units, and can be interconnected through the Type-C interface. More importantly, the Type-C interface not only supports data transmission, but also power transmission. Provides simpler power management for industrial HUB systems, reducing the complexity of power lines and cables.

Type-C connectors provide greater durability and reliability

Industrial environments are usually harsh, and equipment often faces challenges such as vibration, high temperature, moisture, and dust. Type-C connectors adopt advanced mechanical design and have higher anti-interference and stronger resistance to plugging and unplugging durability. In industrial HUB applications, this connector can effectively reduce connection failures caused by frequent plugging and unplugging or harsh environmental conditions. The design of the Type-C connector allows it to maintain good contact performance even when plugged and unplugged multiple times. , further improving the reliability of the equipment and its ability to operate stably for a long time.

Type-C connector optimizes power supply and energy-saving performance

The Type-C connector not only supports efficient data transmission, but also has excellent power transmission capabilities. It can provide a maximum power output of 100W, meeting the power needs of most industrial equipment. In an industrial HUB, many devices require data transmission at the same time and power supply, the Type-C connector can simplify Streamline this process and avoid the use of multiple interfaces and cables, reducing system complexity and energy consumption. In addition, Type-C connectors support more efficient power management, which helps industrial equipment perform in terms of energy saving, especially In the case of long-term operation, it helps to improve the overall system performance and reduce operation and maintenance costs.

Type-C connector promotes the development of industrial Internet of Things

With the rapid development of the Industrial Internet of Things (IIoT), the interconnection between devices has become particularly important. Type-C connectors play a vital role in the Industrial Internet of Things with their powerful data transmission capabilities and power management functions. role. The industrial HUB system needs to process data from various sensors and perform The Type-C connector provides a more stable and efficient connection method for these devices to collect massive information from monitors and data acquisition devices. More importantly, the Type-C interface not only supports high-speed data transmission, but is also compatible with video, audio, etc. A signal format that provides support for the versatility of industrial equipment.

Future development and application trends of Type-C connectors

As the requirements for data processing and device interconnection in the industrial field continue to increase, the application prospects of Type-C connectors in industrial HUBs are very broad. In the future, Type-C interfaces will continue to move toward higher transmission speeds and stronger power support direction of development, promoting the popularization of more high-end industrial equipment. In addition, with the introduction of emerging technologies such as 5G, AI, and intelligent manufacturing, Type-C connectors will play an important role in more complex industrial systems and become the basis for building intelligent, One of the core components of automated production lines.

Type-C connector is becoming an important part of the industrial HUB field with its high-speed transmission, strong compatibility, durability and power management capabilities. Whether it is improving data transmission efficiency, optimizing device compatibility, or energy saving and power supply In terms of electronics, Type-C connectors have shown unique advantages. With the continuous advancement of the industrial Internet of Things and smart manufacturing, the application prospects of Type-C connectors will be broader and become one of the key technologies for future industrial equipment interconnection and system integration. one.