The Importance and Implementation Strategy of Constant Temperature and Humidity Test of TYPE-C Base

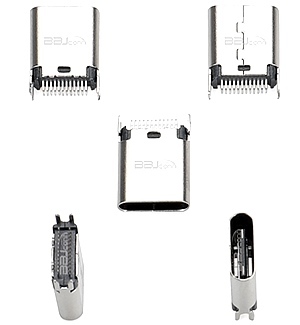

TYPE-C female seatAs an interface widely used in modern electronic equipment, its performance and reliability directly affect the overall quality of the equipment. In the process of R&D and testing of electronic products, constant temperature and humidity testing is to ensure that the TYPE-C female socket performs well under various environmental conditions. Key steps for stable operation. This article will discuss the necessity of constant temperature and humidity testing of TYPE-C base, implementation methods and its application in product development.

The reliability test of the TYPE-C female socket is not only related to the performance of the interface itself, but also to the use experience of the entire product. With the development of technology, the TYPE-C female socket has gradually replaced the traditional interface and become the mainstream choice for data transmission and charging. .In order to ensure that the TYPE-C socket can connect and transmit data normally under different temperature and humidity environments, constant temperature and humidity testing is particularly important. Through this test, engineers can detect potential problems in advance and avoid failures after the product is put into the market. .

The constant temperature and humidity test of TYPE-C female base is usually carried out in specialized laboratories. These laboratories are equipped with advanced constant temperature and humidity equipment, which can simulate various environmental conditions. The test is generally divided into several stages: First, put the TYPE- The C socket is placed in a preset high-temperature and high-humidity environment for a certain period of time to observe its endurance. Then, it is placed in a low-temperature and low-humidity environment for comparison. This process can effectively evaluate the TYPE-C socket Stability and adaptability in extreme climatic conditions.

The material and structural design of the TYPE-C socket also play an important role in the constant temperature and humidity test. When selecting materials, you need to consider their thermal expansion coefficient and moisture absorption capacity. For example, some plastic materials may deform or deform in high temperature and humid environments. Loss of strength, so choosing the appropriate material has a direct impact on the test results. In addition, the welding process of the TYPE-C socket also needs to undergo strict inspection to ensure that it will not cause problems such as poor contact or breakage under constant temperature and humidity conditions.

The constant temperature and humidity test results of the TYPE-C socket are of guiding significance for product improvement and optimization. By analyzing the test data, engineers can identify the weaknesses of the interface under different environmental conditions and then make improvements. For example, if a certain model is found The TYPE-C female seat has corroded in a high-humidity environment. Engineers can consider replacing moisture-proof materials or optimizing the sealing design to improve its service life and reliability.

The constant temperature and humidity test of TYPE-C female base is not only a technical work, but also a systematic quality assurance measure. By implementing this test, companies can better control product quality, reduce after-sales maintenance costs, and improve customer satisfaction. Satisfaction. In the fierce market competition, ensuring the high performance and high reliability of TYPE-C female base is an important way to win the trust of consumers.

The future development trend of TYPE-C socket is also closely related to constant temperature and humidity testing. With the development of emerging technologies such as 5G and IoT, the performance requirements for interfaces will be more stringent. In order to adapt to future market needs, engineers need to constantly update tests Standards and methods to ensure that the TYPE-C socket can meet higher performance requirements. This is not only a reflection of technological progress, but also a commitment to user experience.

In summary, the constant temperature and humidity test of TYPE-C socket is crucial in the development process of electronic products. Through this test, engineers can effectively evaluate and optimize the performance of TYPE-C socket to ensure its performance in various environments. Stability under conditions. In the future, with the advancement of technology, constant temperature and humidity testing will play a more important role in the research and development of TYPE-C sockets, providing users with more high-quality and reliable products.