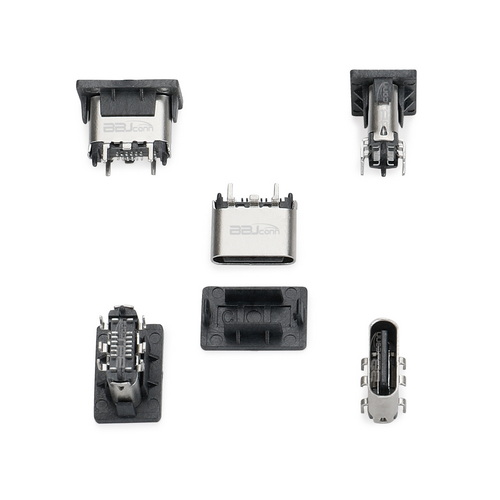

Type-C fast charging connector injection molding difficulty analysis and technological breakthroughs

In the field of modern mobile devices,Type-C fast charging connectorIt has become one of the standard features in the charging field, and its high-speed transmission and fast charging characteristics are favored by consumers. However, the technical challenges behind it cannot be ignored. This article will provide an in-depth analysis of the difficulty of injection molding of Type-C fast charging connectors. , and discuss corresponding technological breakthroughs.

Design complexity of Type-C fast charging connector

The design of Type-C fast charging connector not only includes its external shape, but also involves the internal circuit structure and charging control module. The application of injection molding technology in connector manufacturing makes its internal and external integration possible. However, the complexity of the connector structure The nature increases the difficulty of injection molding. Manufacturers must face the challenge of how to ensure that the precise layout of the connector's internal circuit is not damaged during the injection molding process.

Material selection and thermal stability of Type-C fast charging connector

During the injection molding process, the choice of material is crucial to the quality of the Type-C fast charging connector. The connector needs to withstand frequent plugging and unplugging and high-temperature charging, so its material must have excellent thermal stability and wear resistance. .Manufacturers need to balance cost and performance when selecting injection molding materials to ensure the service life and stability of the connector.

Precision control and cost challenges in the injection molding process

There are complex circuit structures and tiny parts inside the Type-C fast charging connector, which requires highly precise control in the injection molding process. Cost challenges also arise, because higher precision is usually accompanied by higher precision. High manufacturing costs. How to effectively control costs while ensuring connector quality is an important task faced by manufacturers during the injection molding stage.

Sealing and waterproof technology of Type-C fast charging connector

With the widespread use of mobile devices, the requirements for waterproof performance of connectors are increasing day by day. As a charging port, the waterproof performance of Type-C fast charging connector is particularly critical. During the injection molding process, how to achieve effective sealing of the connector has become an issue. A technical challenge. Manufacturers need to use advanced waterproofing technology in the injection molding process to ensure that the connector can work properly in a humid environment.

Technological breakthroughs and future development trends

In order to overcome the problems in the injection molding of Type-C fast charging connectors, manufacturers have made active innovations in material research and development, injection molding process control, waterproof technology, etc. Using advanced injection molding equipment and technology, combined with the use of high-performance materials, It can effectively improve the manufacturing accuracy and stability of Type-C fast charging connectors. In the future, with the continuous advancement of technology, we are expected to see more technological breakthroughs in the injection molding of Type-C fast charging connectors, which will bring more benefits to mobile devices. A more advanced, reliable charging solution.

The difficulty of injection molding of Type-C fast charging connector is a complex and critical issue, which is directly related to the performance and stability of the connector. When facing this problem, manufacturers need to continue to innovate technology and find more advanced materials and processes to cope with the market's increasing demand for connector quality and performance. Through technological breakthroughs, Type-C fast charging connectors will be able to better meet users' needs for efficient and stable charging, and promote the field of mobile devices development.