Type-C interface connector service life test analysis

along withType-C interfaceWidely used in electronic equipment, its reliability and service life have become the focus of users and manufacturers. In order to ensure the stability and durability of the product, Type-C interface connectors must undergo strict service life tests. This article will detail Analyze the service life testing method and importance of Type-C interface connector.

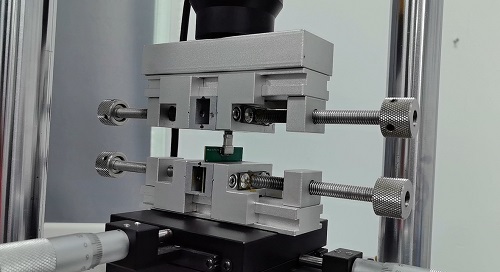

Mechanical durability testing of Type-C interface connectors

The mechanical durability test of Type-C interface connector is an important means to evaluate the stability of its physical connection. This test simulates daily use through repeated plugging and unplugging operations, and detects the wear and damage of the connector during long-term use. Usually , Type-C interface connector needs to pass at least 10,000 plug and unplug cycles to ensure its durability in actual applications. Some high-end products even require 20,000 or more plug and unplug tests to provide higher reliability performance and user satisfaction.

Environmental durability testing of Type-C interface connectors

The environmental durability test of Type-C interface connector is designed to evaluate its performance stability under various extreme environmental conditions. This includes temperature cycle test, humidity test and salt spray test, etc. The temperature cycle test is passed in high and low temperature environments Repeated cycles to verify the connector's reliability under extreme temperatures Reliability. The humidity test evaluates the corrosion resistance of the connector in a high-humidity environment, while the salt spray test simulates the corrosive environment in a marine climate to detect the corrosion resistance of the connector. These tests ensure that the Type-C interface connector performs well under different conditions. It can work stably in any environment and meet the needs of the global market.

Electrical performance testing of Type-C interface connectors

The electrical performance test of the Type-C interface connector is an important step to ensure its current carrying capacity and signal transmission quality. The test content includes parameters such as contact resistance, insulation resistance and withstand voltage. The contact resistance test measures the resistance of the contact points of the plug and socket value to evaluate the transmission efficiency of the connector. Insulation The resistance test verifies the insulation effect between different contact points inside the connector to prevent short circuits and leakage. The withstand voltage test tests the insulation performance and withstand capability of the connector in a high-voltage environment by applying high voltage. These tests ensure that Type-C Interface connectors can transmit current and signals stably and efficiently.

Mechanical shock and vibration testing of Type-C interface connectors

The mechanical shock and vibration test of the Type-C interface connector evaluates its structural strength and stability by simulating various shocks and vibrations during transportation and use. The mechanical shock test detects the impact of the connector by applying impact forces of different strengths. Performance changes during external impact. The vibration test verifies the reliability of the connector in a long-term vibration environment by applying vibrations of different frequencies and amplitudes. Through these tests, it is ensured that the Type-C interface connector performs well during transportation, installation and use. It can maintain stable performance and is not easily damaged.

The Importance of Durability Testing for Type-C Interface Connectors

Durability testing of Type-C interface connectors is crucial to ensure product quality and user experience. High-quality Type-C interface connectors can not only extend the service life of the device, but also improve user satisfaction and trust. For For manufacturers, through strict durability testing, they can discover and solve potential problems in product design and manufacturing, and enhance the market competitiveness of their products. At the same time, durability testing is also necessary to obtain various quality certifications and enter the high-end market. condition.

The Type-C interface connector's service life test covers many aspects such as mechanical durability testing, environmental durability testing, electrical performance testing, and mechanical shock and vibration testing. These tests ensure that the Type-C interface connector is durable in various usage environments. It can show excellent performance and stability, thereby meeting users' needs for high-quality connectors. In the future, with the continuous advancement of technology and the increase of market demand, the durability test of Type-C interface connectors will be more perfect, providing Provide users with more reliable products.